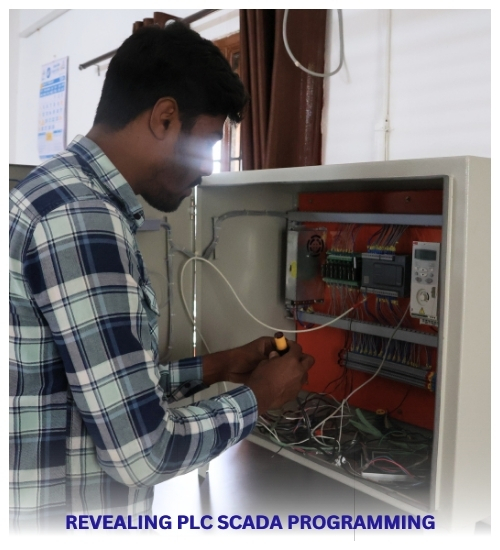

Industrial automation is an ever-evolving field that relies heavily on two key techniques: PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition).

These two techniques work together to ensure seamless operations and control. It is important to understand their separate capabilities and interdependencies in order to gain a deeper insight into the dynamic field of industrial automation.

In this context, revealing PLC SCADA programming becomes a crucial aspect of industrial automation.

A programmable logic controller (PLC) is a small and secure computer made specifically for industrial environments.

It receives real-time information from numerous sensors and actuators, processes it using pre-programmed logic rules, and takes necessary actions accordingly.

You can think of it as the “brain” of an industrial machine which makes decisions based on predetermined parameters and takes actions on-the-fly.

Programmable Logic Controllers (PLCs) can be programmed using special software that uses graphic languages like ladder logic that resemble electrical circuits.

This programming method makes it easy to set conditions (inputs) and their actions (outputs) were using symbols such as contacts, coils, and timers.

For instance, an application called ladder logic can instruct a PLC to activate its pump when pressure sensor readings drop below an acceptable threshold value.

SCADA systems offer a comprehensive view of industrial processes. Unlike PLCs, which specialize in real-time control, SCADAs act as an interactive monitoring or supervisory control interface?

They gather data from multiple PLCs and display it in an easily readable format. The interface also permits manual intervention when required, making SCADAs the watchful eyes over all industrial operations.

SCADA software employs Human-Machine Interfaces (HMIs) to present real-time process information to users, allowing them to monitor patterns, review past events, and set alarms when crucial incidents occur.

Additionally, it facilitates remote process control by configuring these visualization elements and communication protocols to ensure seamless data exchange via PLCs.

Integrating PLCs and SCADA systems provides superior control and monitoring capabilities.

At Nu Intelligence, we believe that practical experience gained through training or internships is essential to increase understanding and apply knowledge effectively in real-life scenarios.

Our mission is to support automation by offering comprehensive training programs that empower the future generation of automation experts.

We strive to equip individuals with the capabilities and skills required to become proficient in PLC/SCADA programming. Our training programs include both theoretical and applied training to ensure that our graduates can make a successful career in their chosen field.

Empower yourself with the skills to control and monitor complex industrial processes. Our comprehensive PLC and SCADA course equips you with the knowledge and hands-on experience to become a valuable asset in today’s automated world.

Understand the hardware, software, and programming languages (ladder logic, function block diagrams) used to control industrial machinery.

Master the software for monitoring, controlling, and acquiring data from PLCs and other industrial devices.

Gain hands-on experience through real-world scenarios, simulations, and projects, building your problem-solving and troubleshooting skills.

PLC and SCADA programming are essential components of modern automation, playing a crucial role in ensuring reliable and cost-effective operations in various industries.

By understanding their unique functions and synergies, individuals can explore exciting possibilities in this dynamic field. With the right education and motivation, anyone can contribute to shaping the future of industrial automation and be part of the next generation!

Phone : +91-9422016801,

+91-7843016801, +91-9730016801

E-mail : nuinagpur@gmail.com, nuintelligence@gmail.com